Our aim is to provide the best quality Consultancy and service regarding various problems pertaining to the civil field.

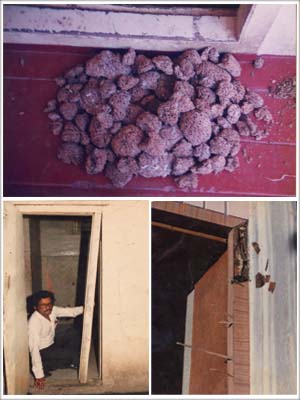

Pest ControlTermite Control

Wood Borer TreatmentRodent ControlAnts and Other Domestic PestMosquito ControlBedbugs Treatment. |

Water ProofingTerrace water proofingSunken portion treatmentFelt workTapper roof TreatmentPressure GroutingExpansion Joint FillingTerrace Crack Treatment |

Demolishing, Core Cutting, RebarringDemolition by breakers for alteration workFull building demolitionCore CuttingRebarringGroove Cutting in Floor |

Industrial Flooring, VaccumDewatering FlooringVDF FlooringGrano FlooringEpoxy FlooringBrushable Floor PaintingSelf Levelling |

The Pre construction anti termite treatment will be done in three stages. In the first stage the treatment is done in the foundation level, after completing the earthwork and before laying the metal concrete (PCC).The sides and bottom of the foundation is completely sprayed up to the ground level irrespective of the depth of the foundation. The termite colonies if any are detected, removed and chemical is injected into the place from where the colonies are removed.

The second stage of the treatment is done at the flooring level, after consolidation of sand and before PCC. Each and every Sq.Ft. corner is punched and chemical is poured into it. The entire carpet area is treated with chemical and the junction of wall and the floor area is completely drenched with chemical.

The third and final stage of the treatment is done around building, after consolidation of sand and before the flooring concrete is laid, About one foot around the building along the running foot is treated with chemical.

Rodding may be required to make the chemical go into the soil. This will prevent the termites, entering in to the building. These are the treatments adopted for the preconstruction anti termite treatment. The chemical used is called chloropyriphos. The chemical is mixed with water in the ratio 1:50. We,also give you a guarantee for ten years from the date of the completion of the job.

As per the site condition certain required changes are adopted and followed by our technically qualified people.

In order to make the chemical penetrate under the floor and in to the wall drilling is done. The drilling in the floor is done at one foot interval near the junction of wall and floor area along the running foot. Each and every rft will be drilled and chemical is injected into the holes. The entire carpet area is sprayed with the chemical.

Drilling is done around the wooden frame in an abtuse angle. This is also done at one foot interval. Then the chemical is injected into the drilled holes. This Chemical will penetrate in to the holes and will arrest all the termites. Wall to wall spraying also is done and the entire floor area is sprayed with the chemical. This is to create an atmosphere inside the building to protect the same from termites.

Outer treatment is done around the building along the running foot in the plinth protection area to form a poison barrier. This will prevent the termites from entering into the building . About two days may be required for completing the entire job. On the first day of the treatment drilling, chemical injecting and spraying are completed. On the second day grouting of drilled holes using cement mortar and white cement is done.

A guarantee, of five years period is given for post construction treatment from the date of completion of the job. During our guarantee period if your good selves find any unexpected reoccurrence of termites, the work will be under taken free of cost.

Wood borers are insects that bore the wood and it make holes very deeply. There by spoiling the wood .These can be arrested by fumigation.

This is done by keeping the poisoness bites in and around the building.Rodents eat the poisoness bites and die immediately.Glue trap method and the old trap method also can be attapted in the places where the poiseness bites cannot be kept.

The domestic pests like ants, cockroaches, spiders and other flies and lies cannot be controlled permanently. For this we adopt chemical spraying method around the building and affected places inside the building. Periodical treatment is required controlling domestic pests(ie once in every two months) chemical will be changes periodically. So that the insects will not get immuned.

This is done by spraying the chemical over the bushes around the building ,in the wall area inside the building and in the places where water is stagnant.

Treatment for Bedbugs will be done by doing the wall to wall spraying work using pesticides. Spraying will be done around the window sills, around door frames, in the entire wall area inside the building, switchboard corners , joints, cavities.

The upper surface of the concrete is well cleaned using wire brushes. The cracks in the concrete if any are detected then ‘V’ groove is taken in the cracks ,which are cleaned and filled with Polysulphide sealent. The sealent is allowed to set for 12hrs.

Pressure grouting is done in the places where the concrete is weak and in the places where voids exist. This is identified by making the water to be stagnant over the concrete surface. After the setting time the sealent in the crack area is coated with cementanious coating with the net reinforcement. Two coats are made one by one in such a way that the entire crack area is covered.

Then the entire concrete area is coated with the cementanious coating with net reinforcement. So the porosity of the concrete will be arrested. This coating will not allow the water inside. After the coating work, water is made to be stagnant over the coated surface. Leak test is done. Then the coating is protected by plastering using cement mortar.

This is a cementanious coating done over the surface of the sunken portions of the building. This is done in two coatings, first coat is done in the horizontal direction and the second coats done in vertical direction. After the completion of the coating, the entire surface is plastered, to protect the coating. Then Regular curing is done.

This felt work is done by scrapping and cleaning the roof area in such away that the surface made free from fungus. Then the surface is made rough, and one coat of primer is applied by brushing over the cleaned roof surface. The felt is made into smaller pieces by cutting the felt to the required measurement.The C.S.adhesive is applied over the floor area and one side of the felt. The first line of felt is made to stick in the lower end of the slope. The next layer of felt is made by sticking above the first line in such a way that the second layer is made to over lap over the first layer to about 2inches. In the same procedure the 2nd layer is stock overlapping the third layer to about two inches. Thus the entire area of the roof is covered. The edge top most layer is raised over wall and it is inserted into the groove made in the wall. The groove is filled and packed in such a way that the felt is in not being pulled out.

This facilitates the rain water to go directly into the drain pipe. This process prevents the damage of the building and protects it from seepage and other problems.

The tile joints and the gaps in the tapper roof are first filled using filling materials like white cement. After 24hours the roof is coated with a material called Futura-5 which has 3000microns elongation. Two coatings are done one after other with required time interval for drying.

This is done to fill in the voids that occur in the roof concrete; a vertical concrete in sumps and over head tanks. In this method the concrete is drilled with holes of 16”diameter where there are voids. Then a pipe is fixed firmly using plugging materials. Then cement slurry is mixed with (free flow grout) chemical and pumped into the holes, till the voids are filled and with an interval of one square meter then the tube is sealed.

Expansion joint is normally created in the long structures. Before treating the expansion joint it is seen that the gap is 10mm deep. Polysulphide sealent is used to fill the gaps after applying the primer over eighter side of expantion joints.

The demolishing is done using 11E, Machine without causing any damage for the building. The whole building demolishing, may also be carried out.

Demolishing of the building is done up to the desired level. The debris and all the waste materials in the building is also removed and the entire site is cleaned. Levelling the debris is also done if required.

Core cutting upto 8” diameter can be done. This is done to make holes for plumbing line,AC, gas holes,chimneys etc. In this method the diamond bit can even cut the reinforced rods and can give smooth finishing. This can be implemented for bed bolt fixing also, up to holes of 12” depth.

The reinforcement rods 8mm to 20mm are fixed in any concrete structure using German chemicals. The rates for rod fixing can be finalised as per the site condition , location and number of rods.

The groove will be marked in the construction joints, as well as in the perpendicular direction of the construction joints. Grooves are made using groove cutting machine with dimond wheel of 5mm width run with the help of 7.5hp motor The grooves are cleaned and dried using blowers. The groove is then filled with the backer rods and polysulphide sealent after sticking the masking tapes on either side of the grooves. Bitumen can also be filled in the grooves as per the requirement of the client.

This is done by vaccum dewatering flooring or machine flooring. In this work, the channels are fixed upto the desired level as per the instruction of site engineer. Then leveling of concrete is done using screed vibrators and aluminium levelers. Excess water in concrete is removed with the help of vaccum dewatering pumps. Finishing work is done using pulvarisers and smooth power traveller.

Grano flooring is carried out by fixing up buttonmarks and leveling using aluminium levelers. Finishing is also done by with help of pulvarisers and smooth power traveller.

The pre-requisites for good adhesion of the coating are cleanliness, roughness and dryness of the surface. Unless these are ensured by proper surface preparation , a successful performance cannot be guaranteed

So concrete surface is made free from contaminants and dust particles with the help of hard wire brush. Since it is not sufficient,acid etching using 1 part of hydrochloric acid with 2 parts of water is also done. The solution is brushed over the surface and left in contact for 15minutes. Then it is washed off with plenty of water followed by thorough drying with hot water.

In this type, the primer coat reaches tack free state, the base and hardener of the epoxy resin is mixed mechanically and allowed to dry completely .Pin holes are filled using epoxy putty and excess putty is rubbed off using emery and finished to the required level. Second and Third Coat also may be be applied over the first coat and allowed to dry. Total thickness of coating is 400microns.